OverviewParameter Function introduction Electrical with valve

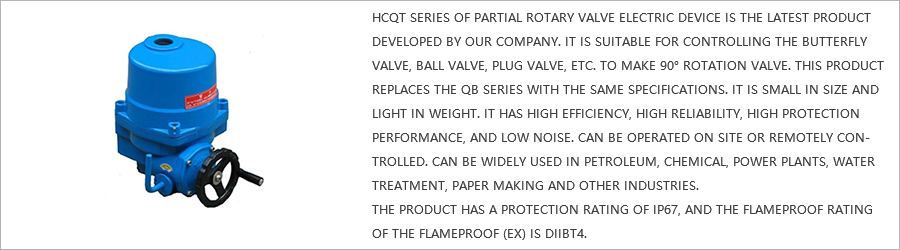

The HCQT series of partial rotary valve electric devices are newly developed products of our company. It is suitable for controlling the butterfly valve, ball valve, plug valve, etc. to make 90° rotation valve. This product replaces the QB series with the same specifications. It is small in size and light in weight. It has high efficiency, high reliability, high protection performance, and low noise. Can be operated on site or remotely controlled. Can be widely used in petroleum, chemical, power plants, water treatment, paper making and other industries.

The product has a protection rating of IP67, and the flameproof rating of the flameproof (Ex) is dIIBT4. This manual applies to ordinary products. If there are other special features, you will be provided with the corresponding "Additional Description."

a) This product complies with the requirements of JB/T8528-97, "Technical Specifications for Ordinary Valve Actuators".

b) The product is outdoor and its protection class is IP67.

c) Ambient temperature: -30 to 70°C.

d) The altitude is not more than 1000m.

e) The relative humidity of the environment is less than 90% (at 25°C)

f) The working environment does not contain strong corrosive media.

g) Do not use in an explosive atmosphere.

h) The product is a short-time work system, rated time 10min.

i) No strong vibration conditions.

3、Main structure and function introduction

a) Motor: Use 220V single-phase motor or 380V three-phase YDF valve special motor.

b) Deceleration mechanism: It is a two-stage worm gear and worm deceleration mechanism.

c) Stroke control and position indication mechanism: Directly lead the camshaft from the output shaft for 90° rotation, and the limit cam also makes 90° rotation for stroke control. The opening index plate is coaxial with the camshaft and is rotated 90° to indicate the valve position.

d) Torque control mechanism: used to control the size of the electric torque. It consists of open and close cams and micro switches.

e) Hand—Electrical switching and manual mechanism: For semi-automatic electric priority, the handwheel operation can be performed after the switching handle is completed. When switched on electrically, the switching handle is automatically restored.

4、Electrical connection with valve

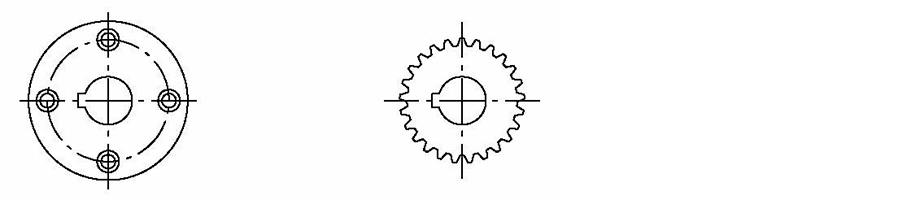

4.1 Valve stem connector (with 4 screws) connection

△ Remove the stem connector and use the “L” wrench to remove the stem connector.

△ Machining the stem joint, according to the shaft diameter of the stem, the size of the key, and the hole and keyway of the stem joint. The direction and position of the keyway should be aligned with one of the four screw holes of the stem joint.

△ Reinstall the stem connector. (There are four kinds of mounting positions on the valve. Users can choose one of them according to their needs.)

△ Check whether the switching direction of the electrical device is consistent with the required switching direction of the valve.

△ Insert the stem connector into the output shaft hole and use the “L” wrench to tighten the four fastening screws.

4.2 Involute Spline Connector Connection

△ Remove the spline connector and press the shaft diameter of the valve stem and the size of the key to machine the hole and keyway of the stem connector.

△ Put the finished stem joint in the direction of the keyway of the stem and put it into the output shaft. If it is not suitable, it can be rotated 1 tooth to fine-tune the angle.

Stem connector as shown: